The mixed-flow pump uses semi-open or closed impellers similar to turbine pumps. Hood Types and Classification 18.

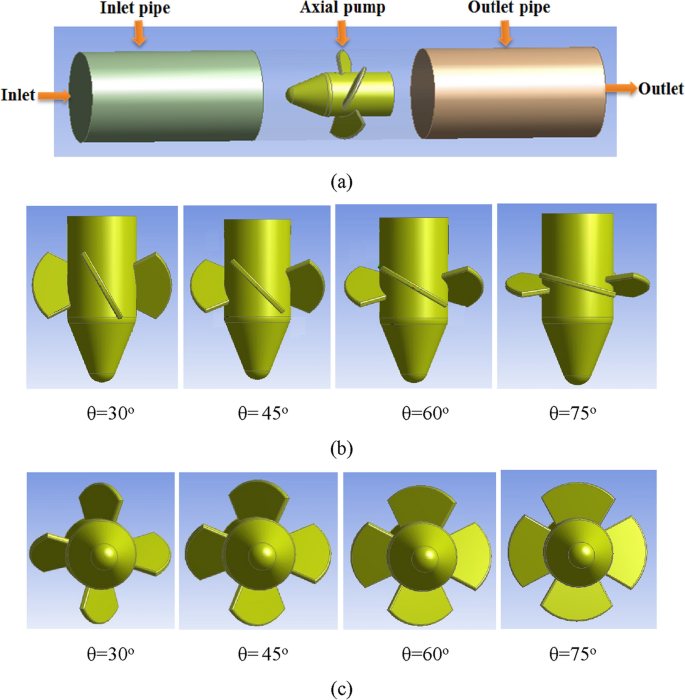

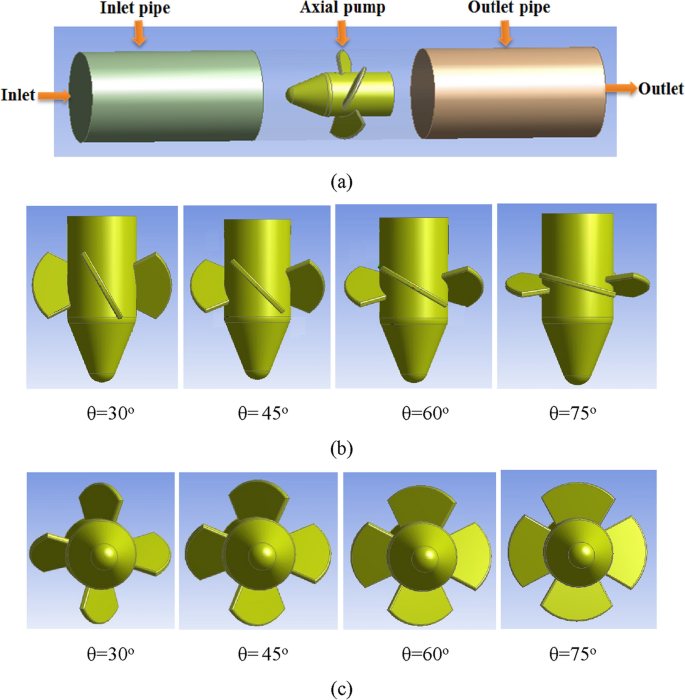

Energies Free Full Text Multi Disciplinary Optimization Design Of Axial Flow Pump Impellers Based On The Approximation Model Html

The impeller and rotor transfer oxygen by mixing the liquid surface while the propeller aspirator injects atmospheric air into the liquid.

. Using Air Multiplier technology was a good start but really addressing the problem meant calling in the experts. Why to select pump with better efficiency. Kinetics and design parameters indicate that batch is a competitive design then use it.

They are used extensively in the state of Florida to control the water level in the canals of low lying. Acoustic engineers are. 13 b shows the effect of the CRA parameter on radial velocity.

HVAC Air Flow IV. The bearing designs and housings are subjected to change. Refers to a design of a centrifugal pump for high flow and low head.

Initially performing optimally at 90 efficiency at lower speeds this design would see many improvements in the subsequent decades in derivatives. Hood Velocity Empirical Equation 15. The equipment used depends on which configuration was utilized for the treatment process.

Utilizing a patented mixed flow impeller design the space-saving configuration of the Vektor-MH and MD maximizes air movement with reduced sound and energy. Guidelines for fan load calculations are adapted from the later SKF PI 113 E publication 1987. Affinity laws for pumps Please go through the below link.

Vektor-MH High Plume and Vektor-MD High Plume Dilution Blower Vektor-MH and Vektor-MD are listed for Electrical ULcUL 705 File 40001 Vektor-MD Patents Manufactured by Greenheck Fan Corp. Downstream of the driven impeller a spring-held stationary turbine was exposed to this angular momentum. In the case of a grid-fed motor the drive efficiency η drive is equal to the motor efficiency η motor and depends on the mechanical.

The ACM Mixed Flow In-Line fan can operate in both horizontal and vertical positions. Affinity laws for centrifugal pumps Positive displacement pump affinity laws Pump affinity laws with example. This pump type combines radial and axial flow producing a conical flow.

Pump Efficiency is the most important factor while calculating power consumption. The value of the specific speed number will provide an indication whether an axial flow pump design is suitable for your application. Standard angle is 45.

The changes in the axial velocity field cause more flow recirculation area due to the pressure gradients. Design Equations Loss Factors and Coefficients of Entry 8. Also known as a propeller pump it produces water flow along the impeller shaft direction.

These have tip speeds between 200 to 300 meters per minute. Vent Axia has designed a complete range of energy efficient Mixed Flow In-Line fans that are now quieter offer two and half times the pressure of conventional axial fans and are dimensionally more compact making them ideal for many ducted applications. Air Flow Entrance and Exit 16.

There are four general configurations for mechanical aeration systems. The major disadvantage of batch reaction now is the hold-up time between batches. This article a reprint from the 1982 SKF S-Range handbook covers the following areas as they relate to fans.

By adding another stage heads from 30 to 40 feet are obtainable. The range should consist of IPX5 rated 100mm and 125mm sizes to meet the Building Regulations compliant design extracting air from wet rooms including kitchen and utility via rigid flexible ducting or throughwall applications with the fewest fans possible supplied with a 7 year warranty. The impeller shape is similar to a propeller.

Average or Slot Velocity 10. High flow rate Low pressure. Bearing arrangements and lubrication.

Radial flow low speed axial flow high speed horizontal rotors and aspirating devices. Axial Flow Turbine Turbo Propeller and Flat Blade Turbine have blades ranging from 3 to 6. In this equation the pump efficiency depends on the pump flow rate Q pump which is equal to the demanded flow rate and in the case of variable speed operation on the rotational speed n see Sections 42 and 52 Section 42 Section 52.

Air Cooling Flow Rate 12. The resulting torque spring torsion was an indication of mass flow. This pump type produces flow in a direction perpendicular to the shaft 90 angle.

Fluctuation in flow motion within a pipe can increase turbulence kinetic energy and hence improve the heat performance. It can be clearly noticed that the CRA high effect. The axial flow pump uses an impeller that looks like a common boat motor screw and is essentially a very low-head pump.

Axial flow impeller propeller approx. See axial flow pumps. Recommended bearing arrangements with spherical.

Low flow rate High pressure. However with complex mechanical designs and high maintenance costs these types of meters have been largely replaced by more robust and less maintenance-demanding designs. Axial flow impeller Acoustic engineering One of the key aspects of the brief for the Dyson Supersonic hair dryer was that it had to be quiet quieter than existing hair dryers.

For Axial Flow Turbine and Turbo Propeller the angle of blade varies from 30 degrees for less viscous liquids to 60 degrees for more viscous liquids. The design effectively combined the inward flow principles of the Francis design with the downward discharge of the Jonval turbine with flow inward at the inlet axial through the wheels body and slightly outward at the outlet. From 140 to 400.

The 100mm DMEV should have variable speed settings of 5-30 ls on trickle and. SCFM and ACFM Corrections 17. The diameter of impeller is 25 to 60 of tank diameter.

And axial flow fans. A single-stage propeller pump typically will lift water no more than 20 feet. Exhaust Hood Capture Velocities 14.

Air Heating Flow Rate 13.

Impeller Vane Model And Grid A Model Of Axial Flow Pump Impeller Download Scientific Diagram

Blade Element Analysis For An Axial Flow Impeller Download Scientific Diagram

Blade Element Analysis For An Axial Flow Impeller Download Scientific Diagram

Analysis Of The Effect Of Various Impeller Blade Angles On Characteristic Of The Axial Pump With Pressure Fluctuations Based On Time And Frequency Domain Investigations Springerlink

0 comments

Post a Comment